AgEBB-MU CAFNR Extension

Green Horizons

Volume 25, Number 3

Fall 2021

If I Was a Carpenter and You Were My Client ...

Lynn Barnickol

Early European carpenters encountering hickory for the first time, would learn it is among the hardest and heaviest hardwoods found in the Colonies. Hickory has unique properties that makes it very useful for daily living. The historical uses for hickory included cabin floors that withstood wear. Hickory was also used for chair and bed frames that were pinned together depending the shrinkage of wood to make strong joints. Hickory could be split, using a froe that resulted in long, thin, narrow trips of wood that were woven to make chair and bed webbing. Hickory is resistant to shock making it ideal for handles for striking tools such as axes, hammers, mauls, and picks, and wagon wheel spokes. The flexibility of hickory made it suitable for hoops for binding staves together for slack and tight cooperage. Carpenters also noticed their hand tools, including saws, planes, draw knives, froes, axes, hammers, and mauls, were suitable for working the wood and creating less splinters only if their tools were kept sharp.

Hickory and pecan, hickory's close relative, are in the Carya genus that is native to the United States. On average, hickory and pecan are denser, stiffer, and harder than either white oak and sugar maple. Hickory is ring-porous, meaning there is a distinct earlywood and latewood bands forming the growth rings. Pecan is slightly less dense, not quite as strong, and is semi-ring porous, giving it a slightly more uniform texture than hickory and aides in identifying hickories from pecan. Carya species are suitable woods for charcoal and used in smoking and grilling meat.

Carpenters learned that hickory is responsive to adhesives, so is suitable for table tops and cutting boards and is pliable, so can be bent for recurve bows and chair backs by steaming. Hickory has been made into baseball bats, poles for vaulting, golf club shafts, and knife handles. Upper grades of hickory and pecan lumber are sold for furniture parts, and flooring, while the lower grades go into pallets, and blocking. Pricing of hickory and pecan is similar to red oak.

Because the woods are very dense, it is more difficult to nail flooring in place and the woods are subject to more warping, shrinking, and swelling as compared to oaks. When using these woods for finished flooring, cabinet and furniture parts there are considerations: Sharp bits are a must for machining as the wood is subject to splintering of the grain. Dull tools generate heat causing the wood scorch turning it black.

Contrasting appearance of hickory and pecan flooring comes from their cream-colored sapwood and brown heartwood. Craft distillers, seeking a unique flavor, may even be finishing their bourbon in pecan barrels. However, pecan does not contain enough lignin to plug the pores of the wood a situation causing barrels to leak.

|

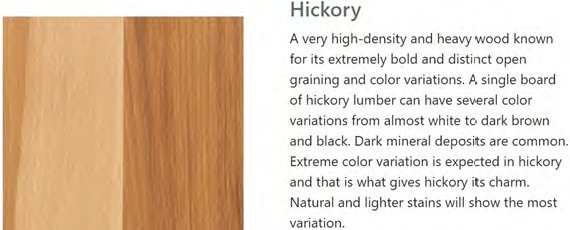

| Image and text is from W.W. Wood Products Inc. Dudley, MO |

If you were my client, in light of the history and ambiance of the Carya genus, we might consider it as the wood that you are seeking for your home or business.

References: A Splintered History of Wood; The Wood Database; W.W. Wood Products Inc., Dudley, MO