To send a message to an author, click on the author's name at the end of the article.

This Month in Ag Connection | Ag Connection - Other Issues Online

Ergovaline is the ergot alkaloid produced by the fungal endophyte in tall fescue that causes fescue toxicosis. When ergovaline, the most concentrated ergopeptine alkaloid found in fescue, reaches 200 to 300 parts per billion (ppb), symptoms begin to be seen. The toxins from the endophyte cause several conditions in animals grazing or feeding on infected fescue.

In all, it is estimated that the losses attributed to fescue toxicosis cost the beef cattle industry well over $609 million a year (1990 data).

Dilution

Rotation

Early Hay Production

Grazing During Periods of Low Concentration

Ammoniation of High Ergovaline Fescue Hay

Reduced Nitrogen Fertilizer Applications

Fescue Replacement

What Doesn't Work

For more information see MU Guide Sheets:

(Author: Jim Jarman, Agronomy Specialist)

This Month in Ag Connection | Ag Connection - Other Issues Online

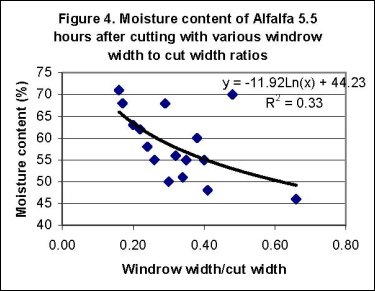

Assuming you harvest at the correct stage, there are some techniques you can use in harvesting to preserve the most of your forage crop. It is important to get the crop to dry as soon as possible. A wide windrow allows for faster drying than narrower windrows. The following chart illustrates that. The one reading that is off the line illustrates the effect of a mower conditioner not being correctly adjusted. The chart is taken from a demonstration at a Wisconsin Farm Technology Day in 2002.

Forage has about 75-80% moisture when cut. It must be dried to 60-65% for haylage or 14-18% for hay. For large bales of hay, bale at 14%.

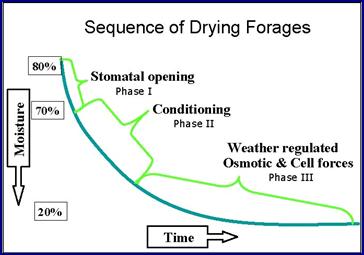

There are three phases of drying forages. They are shown in the following table. The first phase of moisture loss is through the stomates. Stomates are openings in the leaf surface that allow moisture loss to the air to cool the plant and for carbon dioxide uptake. They open in the daylight and close at night. Cutting the forage in a wide swath will maximize stomata exposure to sunlight and encourage rapid drying. Rapid initial drying to lose the first 15% moisture will reduce the loss of starches and sugars and preserve more total digestible nutrients in the forage. This initial loss is not affected by conditioning.

The second phase is moisture loss from the leaf surface and the stem. Conditioning can help increase this drying rate especially on the lower end of the stems.

The final phase is loss of more tightly held water, especially in the stems. Conditioning to break the stems every two inches allows more opportunities for water loss. The following chart shows the phases that have just been discussed. This material is taken from a publication, "Harvesting Impacts on Forage Quality", Dr. Dan Undersander: http://alfalfa.ucdavis.edu/

There are two types of conditioners - roll and flail. Roll conditioners have two adjustments - roll clearance and pressure. These may need to be adjusted often for crop conditions. Adjustment of roll clearance and pressure is important. Minimum clearance must be maintained. If the clearance is too close, excessive damage and loss of plant material occurs. With too much clearance, plant material is not crushed. Too little and too much pressure on the rollers also has the same affect as misadjustment of clearance.

On flail type conditioners, the clearance between the rotating flails and a startionary bar can be adjusted to control the amount of breaking and abrasion that occurs. Flail conditioners were originally developed to condition grasses but are now often used on legumes. Rotor speed should be reduced by about 30% to reduce the impact effect when conditioning legumes. Flail conditioners will likely result in a faster drying rate, but may result in more leaf losses.

Swath manipulation is accomplished with tedders, swath inversion machines and/or raking in phase III of the drying process. Tedding improves drying by spreading the hay over more of the field surface increasing exposure to the radiant solar energy and drying air.

Tedding is most effective if done before the crop gets too dry (above 40% moisture). Tedding has the disadvantage of increased losses, increased fuel, labor and machinery costs. It is sometimes difficult to justify the added costs. Occasional use under difficult drying conditions may bring an economic benefit. When purchasing a tedder look at the total operational costs.

Swath inversion machines gently lift and invert the swath. This exposes the wetter bottom of the swath and speeds drying and reduces the average field-curing time by several hours. The added labor, fuel and machinery costs of the operation are generally greater than the benefit received.

Raking rolls the wetter bottom layer to the top and improves drying. The best moisture content to rake for low loss and good drying is 40%. In dry weather, rake in the evening or early morning when leaves are moist and less prone to shatter. Rake in a manner that will minimize leaf loss. Rake when the hay is dry but tough. Use rakes that handle hay gently or slow the speed of the rake.

Hay should be baled at moisture levels of 14 to 22 %. Use the lower level for large bales. Some people use the twist method for determining moisture. It is probably advisable to compare that to other methods to be sure you are accurate. There are moisture testers on the market today that make this easy for you. You can also use a microwave oven to check moisture. The following is the procedure for checking moisture using a microwave:

% moisture= (initial wt. — final wt.) x 100 (initial wt. - plate wt.)

For more details on the microwave method, see the following web sites:

After you go to all this trouble, don't forget to store your hay for the least loss. Field losses can often be very high. This last year should remind us of the importance of keeping as much of the hay as possible.

For more information on making quality hay see the following web sites:

(Author: Don Day, Natural Resource Engineer)

This Month in Ag Connection | Ag Connection - Other Issues Online

Reports of calving problems in central Missouri have varied significantly. Some producers and veterinarians have reported significant problems with dystocia, stillborn and weak calves in their areas. Other areas have indicated a normal calving season.

If you have been one of the unlucky producers who experienced more problems than normal, it could have been the impact of several environmental factors. These factors include:

(Author: Mark Stewart, Livestock Specialist)

This Month in Ag Connection | Ag Connection - Other Issues Online

Publishing Information

Ag Connection is published monthly for Northeast and Central areas of Missouri producers and is supported by the University of Missouri Extension, the Missouri Agricultural Experiment Station, and the MU College of Agriculture, Food and Natural Resources. Managing Editor: Mary Sobba.